25May

10May

Options in Testing Enclosures-VTT has Plenty!

Options in Testing Enclosures-VTT has Plenty! Our EMC testing enclosures are not one offs! Enclosures are like homes, unique features are necessary to fit the buyer's individual needs! Size is a great place to start in Enclosure design. The larger the product being tested, the larger the enclosure has to be. I'm sure you've heard that big isn't always better. VTT can provide the 3 Dimensional pouch, a compact test enclosure for small objects. On the other hand, VTT is...

27Apr

Your own Test Lab-an RF Shielded Enclosure!

Your own Test Lab-an RF Shielded Enclosure! Best practice suggests Pre-Compliance EMC Testing early and often in product development. The problem is the time and money wasted accomplishing offsite testing! The lead time for testing slows things down as well. The ability to perform testing in your own facility would be great. Many companies have faced this problem over the years. VTT has designed and produced portable testing enclosures for many years. These RF Shielded Enclosures provide the low...

21Apr

Pre-Compliance EMC Testing-Essential in Product Development!

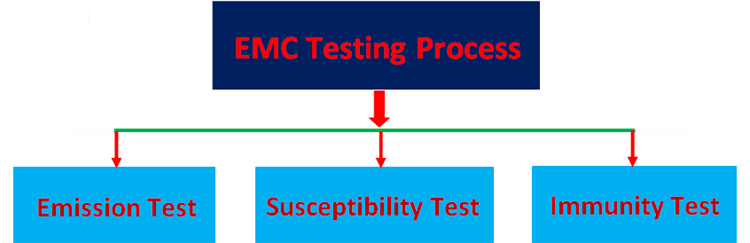

Pre-Compliance EMC Testing-Essential in Product Development! Save time and money in electronic product development! Electronic products must pass EMC Compliance testing before marketing. It isn't essential during product development, but it makes development smoother! EMC testing helps assure that your product meets necessary standards. The best practice is to test early and often during development. Waiting until the product is nearly finished almost assures failure. Failure necessitates "backtracking" to find the problem that caused failure. The failure point must be...

19Apr

RF/EMI Shielded Curtains-Privacy and Separation!

RF/EMI Shielded Curtains-Privacy and Separation! In our lives, we use curtains for privacy, separation, and protection. RFI/EMI Shielded Curtains are used in the same way. RF Shielded curtains are made of conductive metalized textiles. These curtains block the passage of RF and EMI waves. One of the major uses of these curtains is in hospital telemetry areas. They effectively isolate the beds in a "shielded room". This assures that the proper information is transferred...

07Apr

Electromagnetic Compatibility-when devices work smoothly Together!

Electromagnetic Compatibility-when devices work smoothly Together! Devices are like people, they work best when they're compatible. Electronic devices work best when they don't interfere with each other. Electronic devices can be interfered with in several ways. They can be "distracted" by RF interference emitted by nearby devices. This distraction is similar to a co-worker who is always talking. The background "noise" keeps work quality below its potential best. Devices that can be "distracted" are called "susceptible". The answer to susceptibility...

05Apr

RF/EMI Shielding-the Key to EMC!

RF/EMI Shielding-the Key to EMC! Electromagnetic Compatibility Standards must be met prior to marketing devices. The device must perform well in a shared electromagnetic environment. It must not disrupt the performance of other nearby devices. It must not be disrupted by its environmental coworkers. The "potential disruption" is caused by RF/EMI outside of acceptable standards. In the US, the FCC determines these standards. In Canada, Industry Canada determines the standards. Europe requires the "CE" mark that represents...

02Mar

Efficient Best Practice- Frequent EMC Developmental Testing!

Efficient Best Practice-Frequent EMC Developmental Testing! Frequent EMC developmental testing sounds like a lot of work. It also sounds like a waste of precious time. The truth is doing the testing early and often saves a lot of time! "Backtracking" to mitigate/diagnose problems is the real waste of time. Backtracking means "to retrace one's steps" or to "pursue, trace, and monitor". I call it "going back to the drawing board"! Talk about time consuming, that's the definition of backtracking! Pre-Compliance...

24Feb

Electromagnetic Compatibility-when Components get Along!

Electromagnetic Compatibility-when Components get Along! Electromagnetic Compatibility is when components of a device get along. In new devices, the components must work together in a shared electromagnetic environment. If the devices aren't compatible, the device performance suffers. A device should be like a team, many parts working toward one goal. Successful teams are assembled of people who work toward a goal smoothly. Each player executes his job without holding the team back. Similarly, one teammate can adversely affect the function...

23Feb